In the field of industrial automation, the topic of inspection and product testing plays a crucial role, just as much as assembly processes.

Ensuring quality, reliability and repeatability in the production process means overseeing every phase, from the initial stages to the final checks.

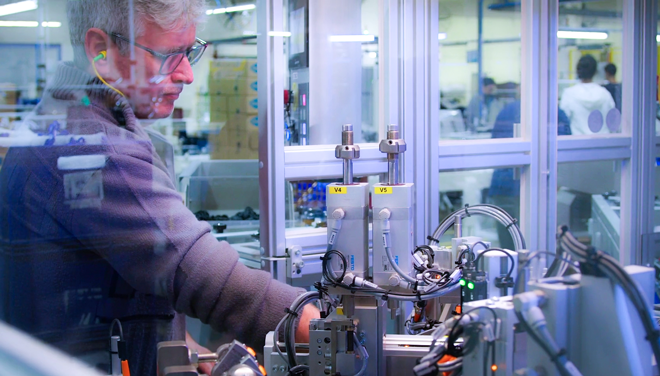

Sinteco stands out for its highly technological solutions for high-complexity assemblies, but the expertise developed over more than 40 years goes far beyond that.

In fact, in addition to automation lines for assembly, Sinteco develops systems dedicated exclusively to testing, quality control and product inspection.

These systems are developed either as stand-alone units - machines or lines dedicated solely to verification activities, such as electrical testing, dimensional inspections or vision-system checks - or as modules that can be integrated into production lines, ensuring operational continuity and process reliability.

Implementing advanced solutions for testing and inspection allows companies to gain immediate and measurable benefits within the production process:

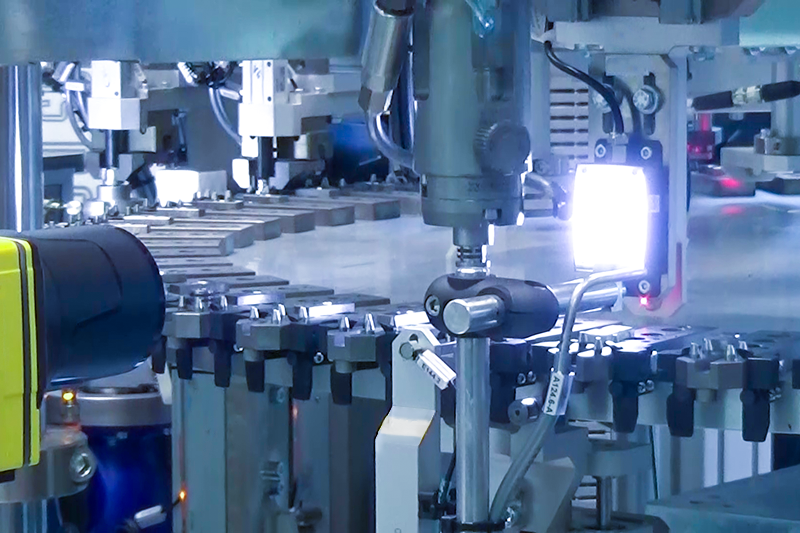

Sinteco’s modular and scalable approach allows the company to provide flexible solutions ranging from a single stand-alone test bench to a full assembly line integrated with automated inspection systems.

Complete lines dedicated to inspection and testing combine various technologies, including prototype stations equipped with vision systems, dimensional and qualitative checks, and stations featuring advanced sensors and integrated diagnostics.

These tools ensure precision, repeatability and defect reduction, contributing to increased overall process efficiency.

If you are evaluating how to optimize inspection, testing or assembly operations within your industrial automation system, our technicians are available: