With the introduction of the magnetic linear transfer, we further expand Sinteco’s range of solutions, offering our customers an even more comprehensive and flexible set of options. The new system integrates perfectly with existing Sinteco hardware and software, enhanced through collaboration with our suppliers and full compatibility with existing safety protocols.

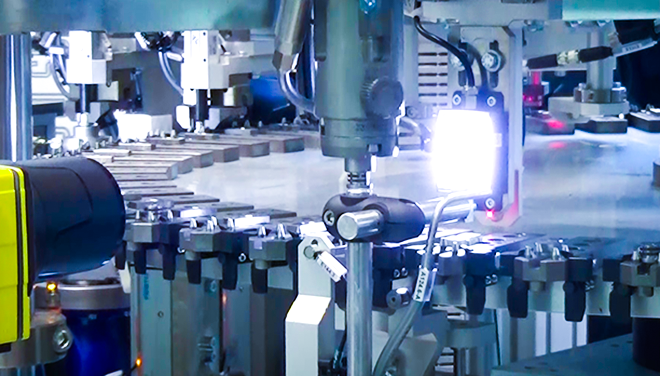

The continuous search for innovative and non-standard solutions has led us to develop a system based on a new transport technology: the magnetic linear transfer, an advanced solution designed to meet the increasingly specific needs of the pharmaceutical, medical, and cosmetic markets.

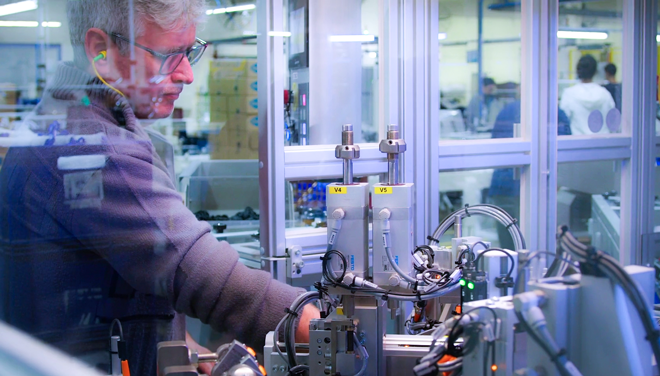

This system was created in collaboration with a long-standing customer in the pharmaceutical sector, resulting in a highly successful pilot project.

The goal was clear: to achieve greater flexibility, modularity, and machine cleanliness while maintaining the construction principles that have always characterized our solutions.

The new magnetic linear transfer was developed to meet the customer’s specific needs and integrated into the designed automated solution. The research focused on the evolution of the traditional Sinteco transfer’s performance, analyzing different suppliers and technologies to identify the most effective and complementary solution to our established platforms.

The result stems from intensive collaboration between the customer and the Sinteco teams. Our R&D department, together with the design team, developed a new magnetic linear transfer that integrates seamlessly with our traditional solutions. This synergy between innovation and proven expertise allows us to enhance our systems’ capabilities, offering customers a complementary, high-performance technology aligned with Sinteco’s design philosophy.

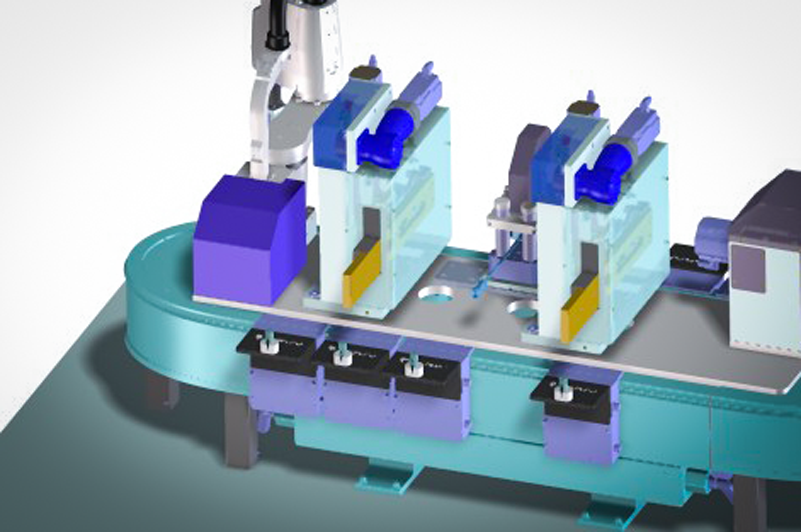

The new Magnetic Transfer introduces a series of real advantages:

In addition, the new system allows the line to be extended without length constraints, covering greater distances and providing increased design flexibility, in synergy with the proven performance of traditional transfers.

This new platform is the result of a shared journey in which internal research, collaboration with customers and suppliers, and attention to market needs have led to a truly innovative technology, capable of combining efficiency, flexibility, and cleanliness.

The magnetic linear transfer therefore represents a concrete step forward toward next-generation automation, designed for the most demanding sectors and oriented toward the future.