St. Olavs University Hospital in Trondheim stands as one of Northern Europe’s most advanced healthcare centres, renowned for its sustainable architecture, streamlined clinical service organization, and innovative approach to pharmacy automation.

Selected through a public tender, we partnered with the hospital to design and implement a comprehensive, state-of-the-art automation system for managing and distributing unit dose medications. This project, in terms of automation and complexity, stands alongside our AGEPS project, fully operational in the Paris area since 2021.

Initial challenges

St. Olavs University Hospital needed to replace its current facility with the most advanced solution available.

The expectations were clear:

- Technological upgrade with a more efficient and scalable system;

- Increased automation to reduce reliance on manual processes;

- Logistical optimization to ensure continuity and safety in therapy distribution.

The implemented solution

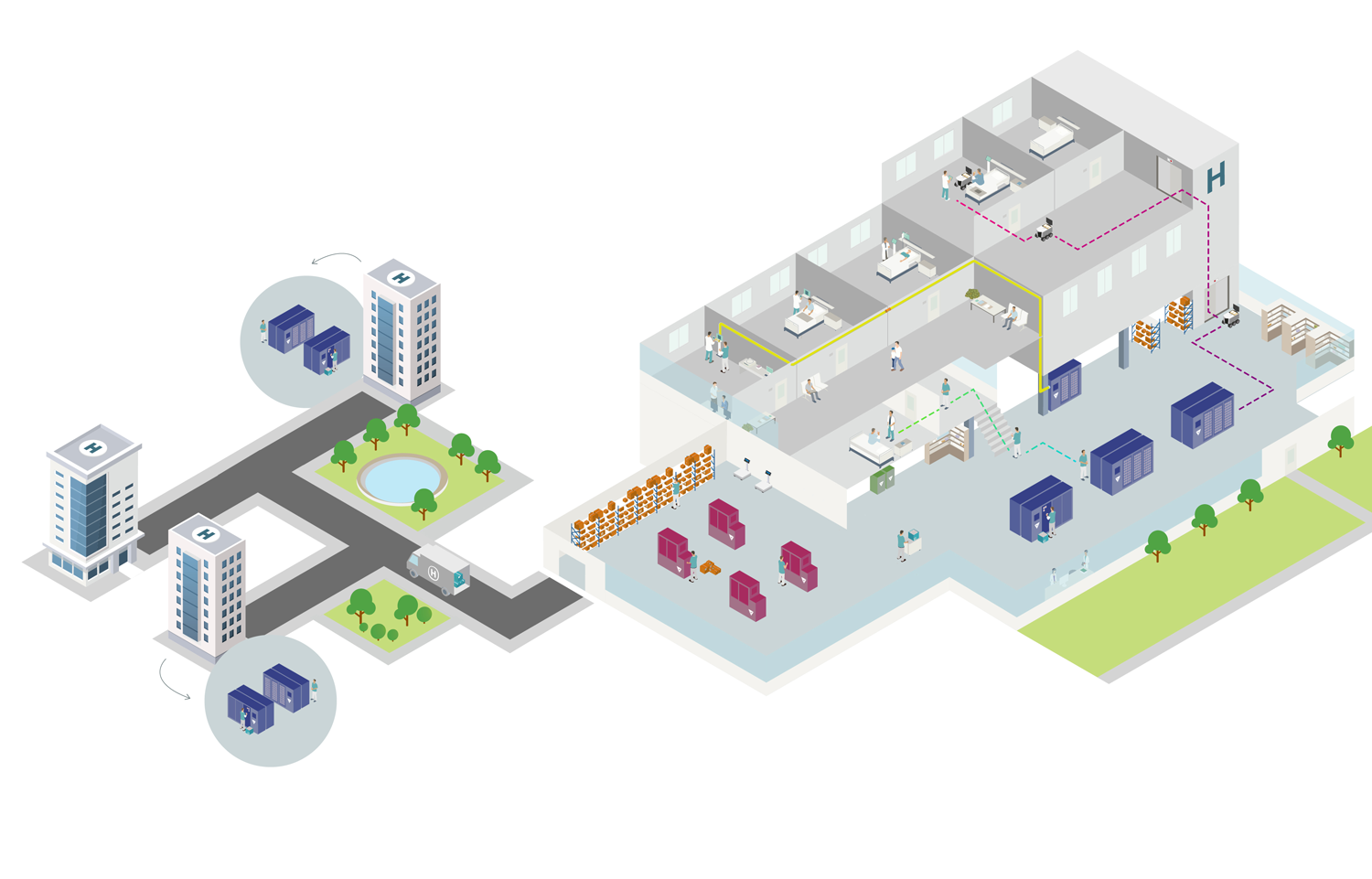

The installed line is fully automated and combines different technologies into a single integrated flow.

The process starts with Calypso, high-capacity, autonomous packaging machines, supported by storage systems engineered to manage significant volumes of unit doses.

Additionally, the automatic transport system ensures constant replenishment and supply of unit doses. The solution is centralized directly within the hospital, ensuring a seamless logistics flow.

Among the therapy distribution systems enabled by automatic transport, part of the medication distribution within the facility can take place via pneumatic tube, which is integrated into the line itself.

The project also includes the installation of Pegasus modules within Regional Pharmacies located in the Midt Norge healthcare area, for the future preparation of personalized therapies for patients.

From a software perspective, the Athena platform enables coordinated management not only of Trondheim’s hospital but also of the connected Regional Pharmacies, turning the system into a true digital hub.

Results and benefits

The new system delivers tangible benefits on several fronts:

- Operational efficiency: significant reduction in drug preparation and delivery times.

- Safety: drastic reduction in human errors in dispensing.

- Productivity: ability to manage high volumes for both St. Olavs and Regional Pharmacies.

- Sustainability: automated packaging in boxes.

- Work quality: more time available for pharmacists to focus on higher-value clinical activities.

A model for the future

The hospital expects significant resource optimization, with a substantial reduction in operating costs and a consequent increase in overall productivity.

Healthcare automation in Norway also addresses a social challenge: in a country with just over 5 million inhabitants and high costs for specialized labor, the adoption of robotic technologies is a strategic step to ensure the sustainability of the healthcare system.

Differentiation and added value

The decision of St. Olavs University Hospital to adopt our solution was driven by distinctive factors:

- Complete and integrated automation of the entire logistics chain, from packaging to transport.

- Multi-hospital management through a single, consolidated software platform.

- Customization of technologies according to the customer’s specific needs.

- Cost-benefit ratio superior to the alternatives available on the market.

Conclusion

The project carried out at St. Olavs University Hospital represents a European benchmark for hospital automation: a system capable of combining efficiency, reliability, sustainability, and innovation.

A reference model for healthcare facilities aiming to evolve toward a safer, faster, and more sustainable drug management.